Complete Guide to Tracks

Posted by Mackenzi Griffin on 11th Jul 2024

A good set of tracks that fits just right and is suited for your job can really make a difference to your loader’s performance, efficiency, and even your own comfort up in the cab. There are so many types of tracks out there, with their own unique benefits. Don’t worry, we’ll guide you through choosing the perfect fit and make sure you are set up to get the longest life out of your track selection.

As you start exploring track options there are a few things you need to look for that will be critical in getting the right fit. It’s important to choose a track that is best suited for your specific needs, for the terrain you operate on the most, and that is compatible with your machine.

Material Quality

It pretty much goes without saying that investing in high-quality, reinforced tracks keeps your loader operational, safe, and efficient, even when the conditions get a little rough. So, how do you know what elements of a track will give you that quality? There are a few features that make up the best tracks but, it comes right down to what they are made of and how they are reinforced. So, let’s talk rubber.

Rubber Compounds

High-grade rubber compounds will provide the durability you need for extended use, while features like tensile strength, abrasion resistance, and heat resistance allow the tracks to withstand the stresses of demanding environments. Flexibility and chemical resistance add to the versatility and lifespan of the tracks, so you can get your money’s worth.

Synthetic Rubber

Tracks made from synthetic rubber compounds like EPDM (ethylene propylene diene monomer) or SBR (styrene-butadiene rubber) offer excellent resistance to wear, weathering, and extreme temperature variations. You can basically roll this rubber over any kind of landscape, no problem. This is a construction site, asphalt, heavy-duty kind of rubber.

Natural Rubber Blend

A blend of natural rubber and synthetic compounds can provide a good balance of flexibility, strength, and resistance to cracking and tearing. Natural rubber is going to last longer on softer terrain like the dirt and grassy terrain of agriculture, and landscaping.

Tensile Strength

Look for tracks with high tensile strength, this is a big deal for heavy-duty applications where the tracks are subjected to constant pressure and movement.

Abrasion Resistance

Tracks with high abrasion resistance will last longer, plain and simple. You especially need this on pavement, gravel, or uneven, rocky ground. This quality helps the tracks maintain their integrity and performance over time.

Heat Resistance

High-quality rubber should be able to withstand the heat generated by friction and exposure to sunlight without degrading. When you’re rolling over hot pavement for hours at a time this is crucial.

Track Reinforcement

Track reinforcement is vital for durability, strength, and in some cases stability. Features like steel cords, reinforced sidewalls, additional rubber layers, and Kevlar integration make tracks more resilient to the daily demands ofthe job site.

You’ll want reinforcement for construction sites where you’re doing things like excavation, grading, and demolition. They can be good in forestry applications as well, where you’re navigating over roots, stumps, and rocks. Even Agriculture settings when you’re hauling heavy equipment loads in unpredictable fields. Pretty much anywhere that your machine is going to face a challenge.

There are different kinds of reinforcements, and each provides its own benefits, in some cases, they are combined for extra strength.

Steel Cords

Steel cords are embedded within the rubber track for extra structural integrity and stretch-resistance. In other words, these cords enhance the tensile strength of the tracks, preventing them from elongating under heavy loads and maintaining shape and effectiveness over time.

Reinforced Sidewalls

The sidewalls of the tracks are reinforced with additional layers of rubber or synthetic materials. Reinforced sidewalls protect the tracks from cuts, punctures, and abrasions caused by sharp objects and rough terrain. They also help prevent the tracks from deforming or tearing, which can lead to premature failure.

Kevlar Reinforcement

Some tracks incorporate Kevlar, a high-strength synthetic fiber, into the rubber composition. Kevlar adds an extra level of resistance to cuts and punctures, further enhancing the durability of the tracks.

Size Matters

Okay, so you know what you’re looking for as far as quality but, the tracks need to fit your machine. Track sizes are specified using three primary measurements: width, pitch, and the number of links. Accurate measurements are critical to the function of the tracks and your machine. Incorrect track size can lead to improper engagement, excessive wear, and potential operator safety hazards. Not to mention the effects on your bottom line.

OEM Specs

Some track manufacturers follow the OEM specs of the original equipment. OEM specs are the original standards and guidelines for the design, performance, and compatibility of tracks for machinery. When tracks meet OEM specifications, it means they are a guaranteed match with the skid steer or compact track loader. If you are fortunate enough to find a track brand that follows the OEM specs of your machine that is obviously going to be your first choice.

Track Width

The width of the track is measured from one side to the other, typically in millimeters (mm).This measurement determines the overall footprint of the machine. The wider the track the more floatation it will have. The narrower the track the more ground pressure it will give you, which equals more traction.

Track Pitch

The pitch is the distance between the centers of two consecutive drive links (or lugs) along the track's length. It is also measured in millimeters (mm).The pitch affects the track’s flexibility and the smoothness of the ride. It also influences how the track fits onto the drive system of the machine. A correct pitch ensures proper engagement with the sprockets and rollers.

Number of Links

This is the total number of drive links (or lugs) around the entire track. The number of links determines the overall length of the track. It is essential for ensuring the right fit around the undercarriage of the loader. Too few or too many links can lead to issues with tension and performance.

There are several ways to determine the size of track and whether your machine is compatible with it. The simplest way is to check the size printed or molded on the side of your current tracks. This usually includes the width, pitch, and number of links (e.g., 320x86x52, where 320 is the width in mm, 86 is the pitch, and 52 is the number of links).

Check the Operator’s Manual

If that is not an option, when in doubt consult the manual. The first and most reliable source of information about your machine. It will provide specific details about the size and type of tracks that are compatible with it.

Measure Manually

If the size has worn off of your current tracks or you lost your owner’s manual, you can do it the hard way.

Width: Measure the width of the track from one edge to the other in millimeters.

Example: If the width is 320 mm, it is written as "320."

Pitch: Measure the distance between the centers of two consecutive drive links along the track's length in millimeters.

Example: If the pitch is 86 mm, it is written as "86."

Number of Links: Count the total number of drive links around the entire track.

Example: If there are 52 drive links, it is written as "52."

Take the time to get it right to save yourself and your machine from harm and money in the long run.

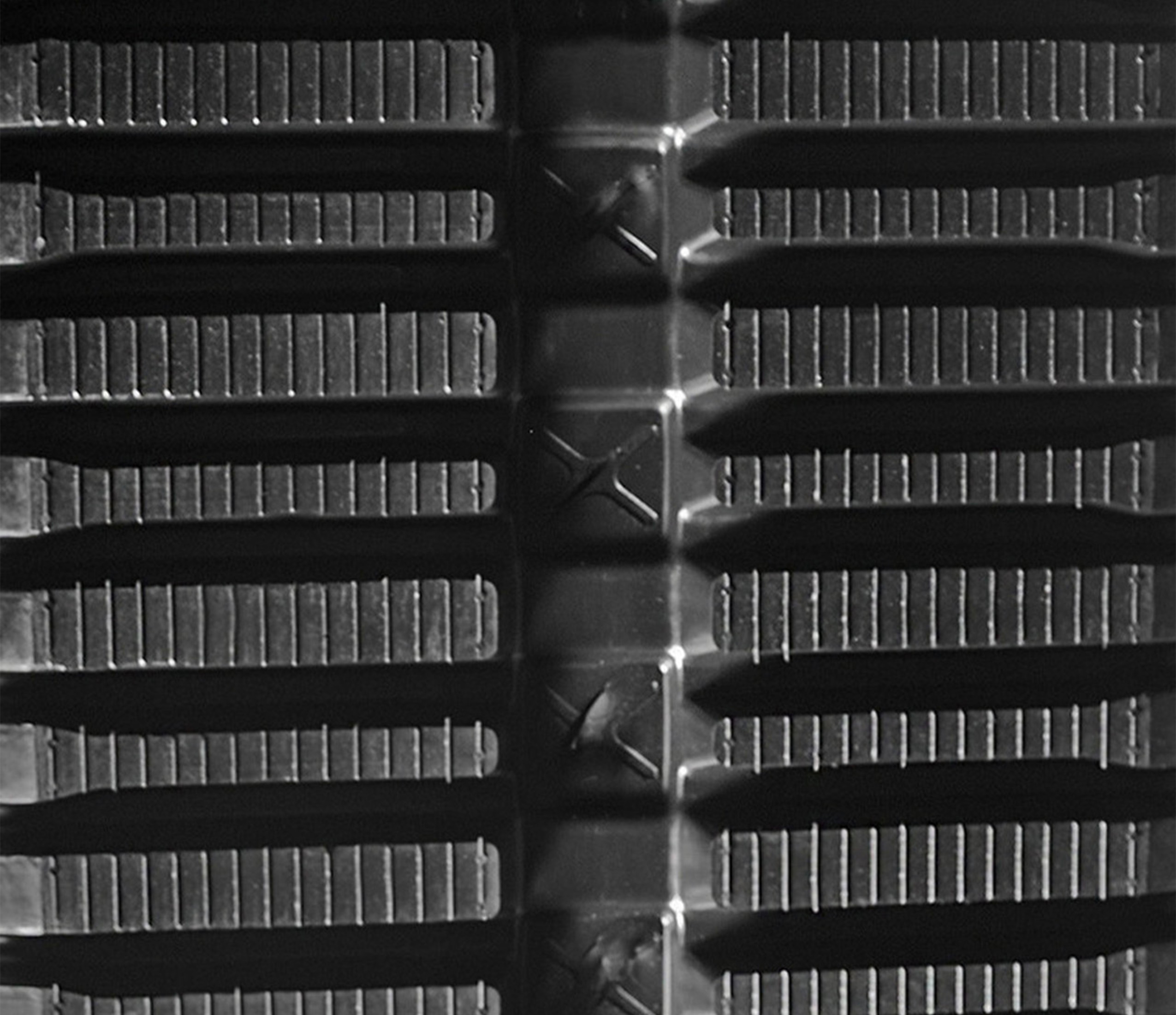

Tread Patterns

Now that we have covered sizing, it is time to get into tread patterns. The tread pattern of a track impacts the machine's overall performance, safety, and traction. You will want to choose a pattern for your specific needs and operating conditions. Each pattern has a specific function and terrain type that they grip the best on.

Traction

The tread pattern determines how well the tracks grip the ground. Specific patterns are designed to bite into the ground or glide across the top. Some perform best on ice, snow, mud and loose gravel and others are designed for harder surfaces like asphalt or forestry. Understanding which type of traction best suits your needs will keep you operating effectively and safely.

Self-Cleaning Ability

Some patterns are designed to “self-clean” by ejecting mud and debris as the track moves to prevent build-up up that could hinder performance. These are great for rolling through mud for long periods because you can keep going without the tracks getting chunked up and bogged down or losing traction.

Ground Pressure Distribution

The tread pattern's design affects how the skid steer's weight is distributed across the ground. Patterns that spread the load evenly help minimize ground pressure, reduce soil compaction, and minimize damage to delicate surfaces. This is great for applications like landscaping or agriculture, where maintaining the integrity of the ground is crucial.

Stability and Ride Comfort

Some tread patterns are designed to minimize vibrations and provide a smoother ride for the operator. This can reduce fatigue plus better stability means better control of the machine.

Durability and Wear

There are tread patterns that are more durable and wear-resistant, for more heavy-duty use. Tracks with durable tread patterns reduce the frequency of replacements and maintenance.

C-Lug

Named for their C-shaped tread pattern, C-Lug Tracks give your machine balanced traction and floatation for mixed terrains, the weight of your machine is more evenly distributed, and the ground pressure is lower. C Tracks are perfect for jobs where you need to minimize damage to the ground, like working on lawns, gardens, or agricultural fields. Plus, this pattern also gives you extra comfort because the arrangement of the lugs lessens the vibrations up to the cab for a smoother and more comfortable ride.

Multi-bar

Multi-bar tracks have a pattern of horizontal bars across the surface of the track. The horizontal bars provide excellent traction on delicate ground like loose dirt, sand, or gravel. They dig into the terrain to give you reliable traction on those loose surfaces and keep you comfortable on hard pavement. The close spacing of the horizontal bars makes this track difficult to keep clean. Mud can often get stuck in there and jam up the track.

Multi-bar is a favorite track for many operators because it is one of the smoothest riding tracks and it leaves the least ground impression. They perform well across slick icy, snowy conditions, soft mud, and hard, rocky ground.

Zig Zag

Also known as chevron or Z-pattern tracks have a distinctive zigzag tread. They are recommended for grading jobs because of their ability to grip the ground when pushing dirt. Some folks refer to zigzags as “arctic tracks” because they maintain exceptional traction on ice and snow as well as wet, soupy mud. The self cleaning design of this track allows dirt and debris to move along the design as they roll. This track is not recommended to run on concrete or asphalt too often since it does not have as much rubber on the face of the track.

Block

Block tracks have a pattern of large, rectangular blocks across the surface. They are the most durable, heavy-duty track because the rubber is so thick and chunky. Each block comes about a 1” to 1.5” off the track face.

They are the roughest riding track but, their extreme durability makes them excellent for forestry, demolition, and some concrete jobs. These are tracks you’ll only want to use where preserving the landscape is not a concern because it leaves heavy imprints in the dirt. Block tracks are not recommended for terrain types that require good traction because they tend to sacrifice grip for durability and have the least amount of traction of any pattern.

Visible Tread Wear

Wear and tear is inevitable but being able to see those first signs of wear in your tracks can really help keep you safe and operational in the long run. Worn treads reduce traction and can compromise the machine's performance. Areas where the tread pattern has worn smooth or become bald are clear signs that the tracks need to be replaced.

Cracks and Cuts

Fine cracks on the surface of the tracks can develop over time due to UV exposure and general use. If these cracks deepen or multiply, it’s a sign of aging and potential failure.

Deep cuts or gouges caused by sharp objects or rough terrain can weaken the track structure and lead to premature failure as well.

Missing or Damaged Lugs

Drive lugs (the internal part that engages with the sprockets) are essential for track function. If lugs are broken, missing, or significantly worn, the track may not engage properly, leading to slippage and reduced efficiency.

Deformation and Stretching

Over time, tracks can stretch, if you notice that your tracks are no longer fitting snugly on the rollers and sprockets, they might be stretched and need replacement. Warped or misshapen tracks can result from prolonged use under heavy loads or uneven terrain. Deformation can cause improper alignment and wear on other undercarriage components.

Exposed Cords or Steel Belts

If the internal steel cords or reinforcement belts start to show through the rubber, that's a critical sign that the track’s integrity is compromised.

Loss of Traction

A noticeable reduction in grip and control, particularly during turns or on inclines, can indicate that the tread is starting to wear out.

Unusual Noises

Squeaking, grinding, or popping noises, can indicate that the tracks are not fitting correctly or that there is excessive wear. Loud banging or clunking noises can signal that the tracks are loose or that the driving lugs are damaged.

Frequent Adjustments Needed

If you find yourself frequently adjusting the track tension to keep it at the recommended level, it may be a sign that the tracks are stretching and nearing the end of their lifespan.

Excessive Vibration

An increase in vibration or a rougher ride can indicate uneven wear or damage to the tracks, which affects the machine’s stability and comfort.

Check Track Alignment

Misaligned tracks can indicate wear in the undercarriage components or the tracks themselves. Your sprockets will have a longer life left staying rounded and without the teeth pointing out. This can cause unnecessary wear on the lugs underneath overall.

Regular Inspection and Maintenance

To prolong the life of your tracks and ensure safety and performance, regularly inspect, and maintain them. Remove debris, mud, and rocks regularly. Maintain proper track tension according to the manufacturer’s guidelines. Be sure the undercarriage components are properly lubricated to reduce wear.

By keeping an eye on these signs and keeping on top of regular maintenance, you will be able to get the most out of your tracks and know when it is time to replace them before they cause significant performance issues or safety hazards. If you are ever in doubt, consult with a professional.

Those are the basics, stay safe out there and feel free to give us a call at 866.966.2538 if you still have questions.