Are Skid Steer Attachments Universal? A Comprehensive Guide

Posted by Hailey Miller on 28th Aug 2024

Skid steers are one of the most versatile and widely used equipment on job sites across various industries, from construction and landscaping to agriculture and forestry. One of the main reasons for their popularity is the wide range of attachments available, which can transform a skid steer into almost any equipment needed for a job. However, a common question among operators, contractors, and equipment buyers is: "Are skid steer attachments universal?" We aim to address this question in detail, covering everything you need to know about skid steer attachments, their interchangeability, and how to ensure compatibility with your machine.

Chapter 1: Understanding Skid Steer Attachments

1.1 What Are Skid Steer Attachments?

Skid steer attachments are specialized tools or implements that can be mounted on the front of a skid steer loader. These attachments allow the skid steer to perform a variety of tasks, including digging, lifting, grading, snow removal, and material handling. The versatility of skid steers is largely due to these attachments, which can be quickly swapped out to adapt the machine to different tasks.

1.2 The Evolution of Skid Steer Attachments

Originally, skid steers were designed for basic tasks like lifting and moving materials. However, as the needs of industries grew, so did the range of available attachments. Over the years, manufacturers have developed specialized attachments for almost every conceivable task. This evolution led to the development of standardized attachment systems, making it easier for operators to switch between different brands and types of attachments.

Chapter 2: The Concept of Universality in Skid Steer Attachments

2.1 What Does "Universal" Mean in the Context of Skid Steer Attachments?

When we say that skid steer attachments are "universal," we refer to their ability to fit and function on a wide range of skid steer models, regardless of the manufacturer. This universality is primarily achieved through standardized mounting systems and couplers, allowing attachments from one brand to be used on skid steers from another brand.

2.2 The Universal Skid Steer Quick Attach (SSQA) System

The Universal Skid Steer Quick Attach (SSQA) system, also known as the Universal Quick Attach (UQA) or Bobcat-style quick attach, is the most common mounting system used in the industry. Introduced by Bobcat in the 1970s, this system has become the standard for skid steer attachments, allowing for quick and easy changes between attachments without the need for additional tools.

The SSQA system uses a standardized mounting plate with two locking pins that secure the attachment to the skid steer. The operator can engage or disengage the attachment by operating a lever from inside the cab or manually from outside the machine. This system has been widely adopted by most skid steer manufacturers, making it easier for operators to use attachments from different brands on their skid steers.

Chapter 3: Factors Affecting Skid Steer Attachment Compatibility

3.1 Size and Weight Considerations

While the SSQA system allows for universal mounting, not all skid steer attachments are compatible with every skid steer. One of the most important factors to consider is the size and weight of the attachment. Skid steers come in various sizes, ranging from compact models to large, heavy-duty machines. Each skid steer has a specific operating capacity, which is the maximum weight it can safely lift and operate.

Attachments, too, vary in size and weight. For example, a large, heavy-duty mulcher attachment might be too heavy for a compact skid steer to handle. Operating an attachment that exceeds the skid steer’s weight capacity can lead to instability, reduced performance, and potential damage to the machine.

How to Check:

- Manufacturer Specifications: Always refer to the skid steer’s and attachment’s specifications to ensure that the attachment’s weight is within the skid steer’s operating capacity.

- Balance and Stability: Consider the balance and stability of the skid steer when using a heavy attachment. Overloading can make the machine top-heavy and prone to tipping.

3.2 Hydraulic Flow and Pressure

Hydraulic flow and pressure are critical factors in determining attachment compatibility. Many skid steer attachments, such as augers, trenchers, and mulchers, rely on hydraulic power to function effectively. The skid steer’s hydraulic system provides the necessary flow (measured in gallons per minute, or GPM) and pressure (measured in pounds per square inch, or PSI) to drive these attachments.

All skid steers come with a standard-flow hydraulic system, which typically provides 15-25 GPM. However, some skid steers can be equipped with an optional high-flow system, which can deliver 26-40 GPM or more. Attachments designed for high-flow systems require this additional hydraulic power to operate efficiently. Using a high-flow attachment on a skid steer with only standard-flow can result in poor performance or even potential damage to the attachment.

How to Check:

- Hydraulic Flow and Pressure Requirements: Check the attachment’s hydraulic flow and pressure requirements and ensure they match your skid steer’s hydraulic system capabilities.

- Standard vs. High-Flow: Confirm if your skid steer is equipped with a high-flow system if you plan to use attachments that require higher hydraulic flow.

3.3 Mounting Plate Compatibility

While the SSQA system is standard on most modern skid steers, older models or specialized machines might use different mounting systems. For example, some older skid steers or mini skid steers may use a different quick attach system that is not compatible with the SSQA.

How to Check:

- Visual Inspection: Perform a visual inspection of your skid steer’s mounting plate and compare it to the attachment’s coupler. Ensure that the dimensions and locking mechanisms match.

- Adapter Plates: If your skid steer has a non-standard mounting system, you can often find adapter plates that allow you to use SSQA attachments.

Chapter 4: Common Skid Steer Attachments and Their Compatibility

4.1 Buckets

Buckets are the most commonly used skid steer attachments, and they come in various shapes and sizes, including general-purpose buckets, rock buckets, and grapple buckets. Buckets are typically universal as long as the mounting plate and weight capacity are compatible with your skid steer.

Compatibility Tips:

- Ensure Proper Fit: Make sure the bucket is the right size for your skid steer and that it attaches securely using the SSQA system.

- Hydraulic Grapple: If using a grapple bucket, ensure your skid steer has the necessary hydraulic hookups.

4.2 Augers

Augers are used for drilling holes in the ground, commonly in construction, landscaping, and agricultural applications. Augers require hydraulic power to operate, making hydraulic flow and pressure key considerations.

Compatibility Tips:

- Hydraulic Flow: Ensure your skid steer provides the required hydraulic flow for the auger.

- Mounting Plate: Check that the auger’s mounting plate matches the SSQA system on your skid steer.

4.3 Pallet Forks

Pallet forks are versatile attachments used for lifting and moving pallets, materials, and other items. Pallet forks are generally universal, but you should ensure that the fork’s frame size and weight capacity align with your skid steer’s capabilities.

Compatibility Tips:

- Weight Capacity: Ensure the skid steer can safely lift the weight of the load on the pallet forks.

- Frame Size: Check that the frame of the pallet forks fits securely on your skid steer’s mounting plate.

4.4 Brush Cutters and Mulchers

Brush cutters and mulchers are heavy-duty attachments used for clearing vegetation, including thick brush, small trees, and overgrown areas. These attachments require significant hydraulic power, and compatibility depends heavily on your skid steer’s hydraulic system.

Compatibility Tips:

- High-Flow Requirements: Most mulchers require a high-flow hydraulic system. Verify that your skid steer is equipped with high-flow capabilities.

- Mounting Plate: Ensure the brush cutter or mulcher’s mounting plate is compatible with your skid steer’s SSQA system.

4.5 Trenchers

Trenchers are used for digging narrow trenches for utilities, irrigation, and other purposes. Like augers, trenchers require hydraulic power to operate, making hydraulic flow and pressure important considerations.

Compatibility Tips:

- Hydraulic Requirements: Check that your skid steer provides the necessary hydraulic flow and pressure for the trencher.

- Mounting Plate: Verify that the trencher’s mounting system matches the SSQA plate on your skid steer.

Chapter 5: How to Determine If Your Skid Steer is Compatible with Attachments

5.1 Reviewing the Operator’s Manual

The first step in determining compatibility is to review the operator’s manual for your skid steer. The manual will provide detailed information about the machine’s operating capacity, hydraulic system specifications, and the type of quick attach system it uses.

What to Look For:

- Operating Capacity: Maximum weight the skid steer can lift.

- Hydraulic Flow and Pressure: Specifications for the skid steer’s hydraulic system.

- Quick Attach System: Information about the type of quick attach system on your skid steer.

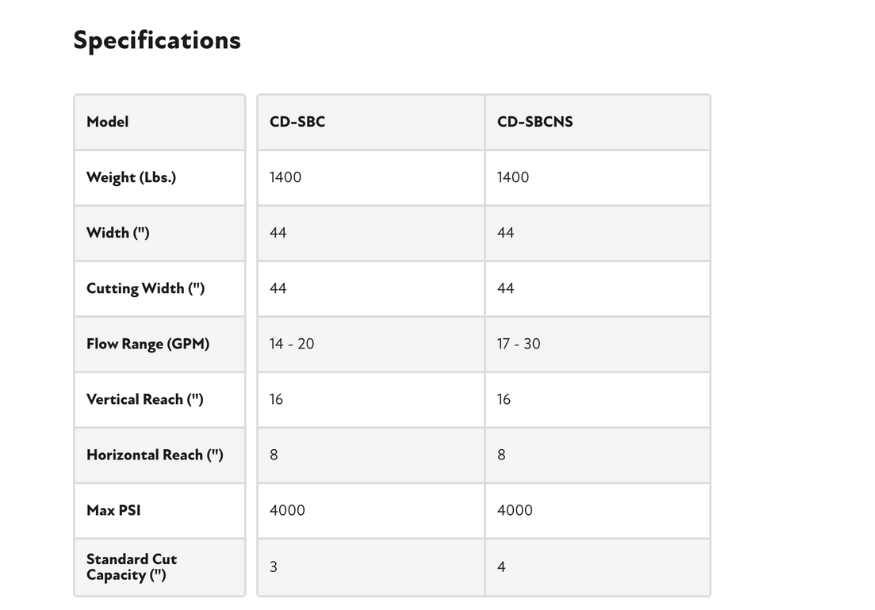

5.2 Consulting the Product Specifications

The Specifications tab on our product pages provides essential information to ensure the attachment you're considering is compatible with your skid steer. Detailed specifications on weight, hydraulic requirements, and mounting compatibility are available to help you make an informed decision.

What to Look For:

- Weight: Ensure the attachment’s weight is within the operating capacity of your skid steer.

- Hydraulic Requirements: Check the flow and pressure needed to operate the attachment and compare it to your skid steer’s hydraulic system.

- Mounting System: Verify that the attachment’s mounting system is compatible with your skid steer’s quick attach system.

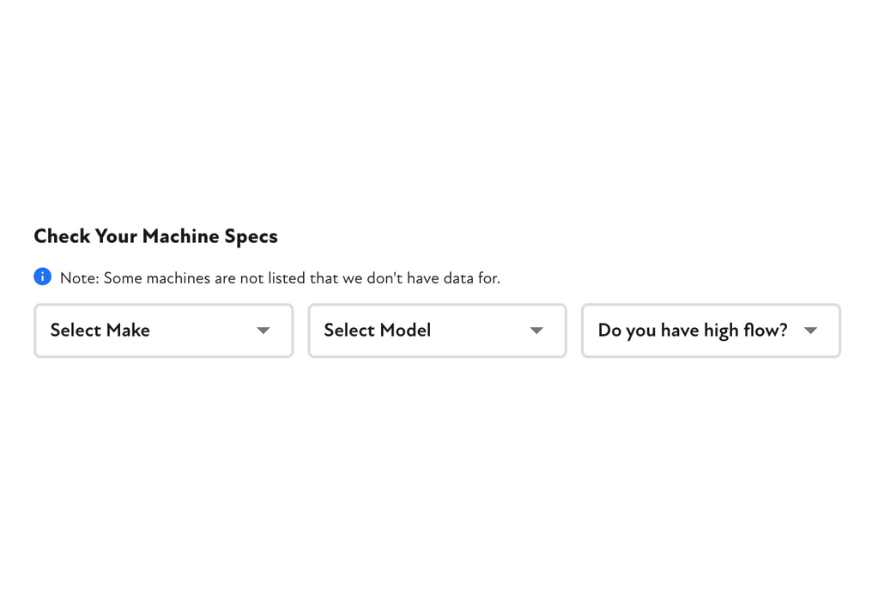

Additionally, use our available database of over 100 skid steer models to cross-reference your skid steer’s specifications with the attachment to confirm compatibility before purchasing.

5.3 Measuring the Attachment Plate and Skid Steer Coupler

If manuals are unavailable, a physical measurement can help determine compatibility. Measure the dimensions of the attachment plate and the skid steer’s coupler to ensure they match.

Steps to Measure:

- Width and Height: Measure the width and height of the attachment plate.

- Pin Placement: Check the placement of the locking pins or other securing mechanisms.

- Hydraulic Connections: If applicable, verify the size and location of hydraulic connections.

Chapter 6: Special Considerations for Older and Specialized Skid Steers

6.1 Older Skid Steer Models

Older skid steer models may not be equipped with the SSQA system, making attachment compatibility more challenging. These machines might use proprietary quick attach systems or have different hydraulic specifications.

What to Consider:

- Adapter Plates: Adapter plates can be used to convert older or non-standard quick attach systems to the SSQA standard.

- Hydraulic Upgrades: Consider upgrading the hydraulic system if necessary

Chapter 7: Our Extensive Database of Skid Steer Specifications

Ensuring that the attachments you purchase will fit your specific skid steer model is crucial for optimal performance and safety. To assist with this, an extensive database of specifications for over 100 different skid steer models is available. This resource allows you to cross-reference your skid steer's details with the attachments you're considering. By entering your skid steer's make and model, you can quickly determine which attachments are compatible, reducing the guesswork and providing confidence in your purchase.

How to Use the Database:

- Search by Model: Input the make and model of your skid steer into the database to find matching specifications.

- Compare Specs: Review the attachment specifications on the product page and compare them with your skid steer's capabilities.

- Compatibility Confirmation: Ensure that your skid steer’s hydraulic flow, operating capacity, and quick attach system align with the attachment's requirements.

While many skid steer attachments are designed to be universally compatible, ensuring that they fit and function correctly with your specific machine requires careful attention to several key factors. These include the type of quick attach system, hydraulic flow and pressure, weight capacity, and the specific requirements of your skid steer model.

Taking the time to verify compatibility can save you from potential frustrations and ensure that your equipment operates safely and efficiently. By consulting the detailed specifications available online and utilizing the database of over 100 skid steer models, you can confidently determine whether an attachment will work seamlessly with your skid steer. This proactive approach helps you make informed decisions, allowing you to fully leverage the versatility and power of your skid steer with the right attachments.

Understanding and applying these considerations will not only enhance the performance of your skid steer but also extend the lifespan of both the machine and its attachments. Properly matched attachments can transform your skid steer into a multi-functional powerhouse, capable of tackling a wide range of tasks with precision and ease.

In conclusion, while skid steer attachments are generally designed to be interchangeable, taking the time to check compatibility ensures that you get the best performance and safety from your equipment. By following the guidelines outlined in this blog and using available resources, you can confidently choose attachments that will enhance your skid steer’s versatility and productivity, helping you to get the job done right every time.